Qingdao Nanchen Resin Sand Vibrating Crushing and Regeneration Integrated Machine

As the core equipment of the foundry used sand recycling system, the resin sand vibrating crushing and regeneration integrated machine synchronously completes the crushing and screening processes of used sand through high-frequency vibration. It efficiently strips the binder film on the surface of sand particles to realize the regeneration and reuse of used sand. Designed specifically for global foundry enterprises to reduce costs, cut consumption and achieve green production, this equipment not only significantly reduces new sand consumption and waste sand pollution, but also improves the quality of regenerated sand, helping enterprises achieve dual enhancement of economic and environmental benefits.

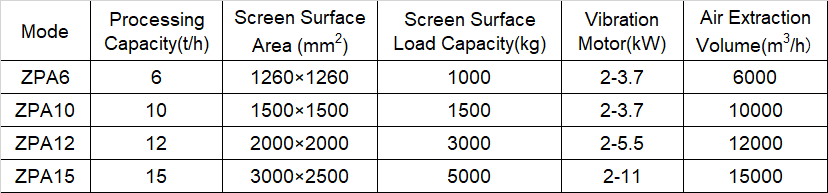

This resin sand vibrating crushing and regeneration integrated machine has four main models, which are adapted to the production needs of enterprises of different scales. The processing capacity ranges from 6-15t/h, and the screen surface area is designed in a gradient from 1260×1260mm² to 3000×2500mm². The load capacity of the screen surface increases with the expansion of processing capacity, and it is equipped with vibration motors of different power ranges to ensure stable power output; the air extraction volume reaches 6000-15000m³/h synchronously, effectively ensuring the cleanliness of the working environment. With optimized process design, the regeneration efficiency of the equipment is increased by more than 30% compared with traditional equipment, the particle size of regenerated sand is uniform, 80% of new sand consumption can be saved, and the rejection rate of castings is significantly reduced.

In terms of structural design, this integrated machine can be customized according to customer requirements. In a previous cooperation case, the customer put forward the demand of limited factory space and the need to adapt to the existing production layout. Therefore, the company adopted a compact structural design when customizing the integrated machine. The equipment height is reduced, and it can be flexibly installed without additional site modification, greatly saving factory space. Key components are made of high-strength wear-resistant alloy steel, which not only ensures the operation stability under continuous working conditions, but also simplifies the operation and maintenance process, realizing the efficient and continuous production required by customers. The application of high-frequency vibration technology enables the synchronous completion of crushing and screening processes, which not only improves the regeneration efficiency, but also ensures the consistency of regenerated sand quality, perfectly meeting customers' dual pursuit of efficiency and quality.

To better serve global customers, Qingdao Nanchen provides customized solutions for resin sand vibrating crushing and regeneration integrated machines. The company's team will conduct in-depth research on customers' production demands, and fully meet customers' needs from capacity matching, site adaptation to environmental protection standard alignment. At the same time, the company provides comprehensive technical support and after-sales maintenance services to ensure the stable operation of equipment in different production scenarios, helping global foundry enterprises reduce costs and increase efficiency through efficient recycling of used sand.