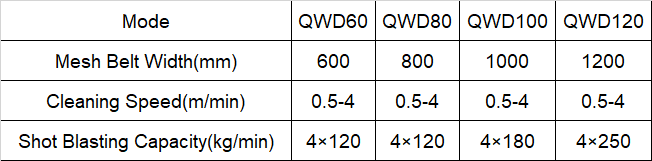

Qingdao Nanchen QWD Series Mesh Belt Shot Blasting Machine

Qingdao Nanchen QWD Series Mesh Belt Shot Blasting Machine is a continuous surface treatment equipment specially designed for small, precision and fragile components. Focusing on the processing needs of thin-walled castings, fragile iron/aluminum alloy castings, ceramics and other parts, it can not only efficiently remove scale, rust and other impurities on the surface of workpieces, but also realize surface strengthening of mechanical parts, providing global customers with stable and reliable precision surface treatment solutions.

This series of shot blasting machines includes four main models with technical parameters adapted to different processing scenarios: the mesh belt width adopts a gradient design from 600mm to 1200mm, which can flexibly meet the conveying needs of workpieces of different specifications; the cleaning speed is adjustable in the range of 0.5-4m/min, which can be freely set according to workpiece materials and processing standards; the shot blasting capacity is configured in grades according to models, among which the QWD120 model has a shot blasting capacity of up to 1000kg/min, balancing high-efficiency processing and precision finishing.

The QWD Series Mesh Belt Shot Blasting Machine features both practicality and cost-effectiveness in structural design: it adopts a wear-resistant alloy steel mesh belt for stable and wear-resistant conveying, ensuring the stability of continuous operation; the shot blaster is equipped with an optimized flow channel design, realizing uniform shot projection and dead-corner-free cleaning of workpiece surfaces; the innovative pit-free structure eliminates the need for complex foundation modification, greatly reducing installation difficulty and initial investment, and is compatible with various workshop layouts. Meanwhile, the flexible projection technology effectively controls workpiece deformation, solving the problem of damage prone to thin-walled and fragile components during processing from a technical perspective.

This series of shot blasting machines has significant advantages in production coordination and operational economy. It is compatible with two operation modes: standalone operation and production line linkage, which can be flexibly adjusted according to the enterprise's production capacity, and can be precisely adapted to both batch processing for small and medium-sized enterprises and automated assembly line production for large-scale factories; the operation process is simplified, with intuitive and convenient adjustment of key parameters; daily maintenance only requires routine inspections and replacement of wearing parts without complex technical support, greatly reducing labor costs. In addition, the high-efficiency shot utilization rate and wear-resistant component design reduce consumable loss and replacement frequency, bringing more advantages in long-term operating costs and providing tangible support for customers to achieve cost reduction and efficiency improvement.

In line with the global development trend of industrial automation and high efficiency, the QWD Series Mesh Belt Shot Blasting Machine has become the preferred equipment for global customers in the field of surface treatment for small precision components due to its precise parameter configuration, reliable performance and flexible application modes. To meet the diverse needs of global customers, the product supports customized services, with parameters or functional configurations that can be flexibly adjusted according to workpiece specifications, processing standards and other requirements. The company simultaneously provides full-process services including professional technical consultation, installation guidance, regular maintenance and spare parts supply, comprehensively ensuring stable equipment operation and efficient capacity release, and delivering customized, high-quality one-stop surface treatment solutions for the processing of various fragile components.